EPS Production Line

- Home

- Products

- Insulation Materials Machinery

- EPS Production Line

Introduction of Expandable Polystyrene

Expandable polystyrene, or EPS for short, is a kind of lightweight plastic foam insulation material produced from solid polystyrene beads. During production, the tiny beads are expanded and consolidated in the process of steam heating and pressure treatment. When heated, the beads are enlarged by the expanding agent as much as 50 times, after which the beads will be fused by pressure into large block of EPS or into the required shape by the moulds.

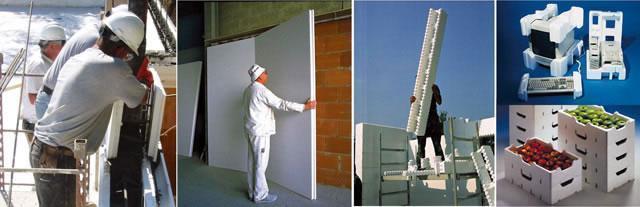

EPS product is well received in construction and packaging industry because of its wide applications. In addition to roof, wall, and ceiling construction, the EPS is also applicable for packaging food, electronic equipment, home appliance, and so on.

Main Configuration of EPS Production Line• Pre-expander

• EPS Block Molding Machine

• EPS Cutting Machine

• Auxiliary Equipments

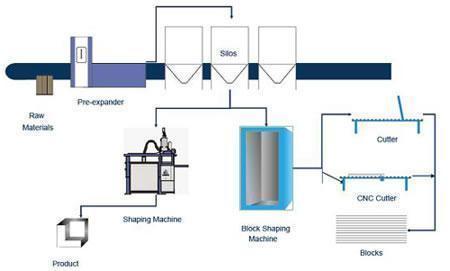

Flow Chart of EPS Production Line

Raw materials -> Pre-expander -> Silos -> Shaping Machine / Block shaping machine -> Cutter / CNC Cutter -> Blocks, and for the detailed information, please refer to the following chart:

Technical Parameters

| Item | Unit | HIM-EPS-2000 | HIM-EPS-3000 | HIM-EPS-6000 |

| Production Capacity (15kg/m3) | m3/h | 20 | 30 | 60 |

| Block Size | m | 2×1.2×1 | 3×1.2×1 | 6×1.2×1 |

| Installed Power | kw | 90 | 90 | 105 |

| Workshop Area | m2 | 1000 | 1200 | 1500 |

Remark: The parameters listed above are for standard configuration. Bespoke product is available from us.

Related Names

EPS Machine | EPS Machinery

English

English Español

Español Русский

Русский Français

Français العربية

العربية